62 FL Chop Rebuild 13

Gettin' there, slow but sure....

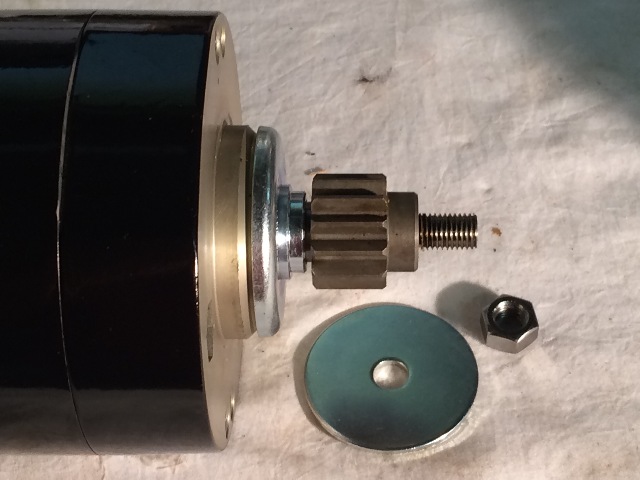

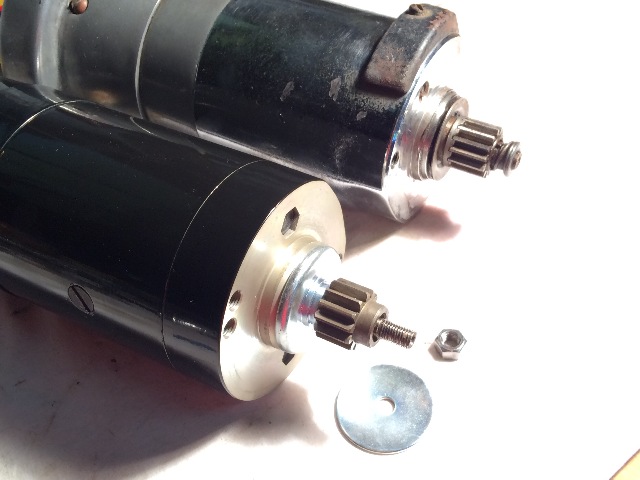

The new 12 volt generator arrived...

but the new drive gear is a sloppy loose fit...

It's supposed to be a snug fit, an easy "press on" fit...

So I'm looking for another gear, that will fit properly...

The original gear on the old 6v generator is in good shape, but I have

plans for that generator down the road, plus it is the high output "police special"

model 58R, and has a special drive gear with a spring loaded ratchet mechanism on it,

so I would rather leave it alone to use on a later project...

Put a new O-ring chain on, 100 links fits perfectly with the wheel adjusted most of the way forward,

but the side plate on the master link would not go on. Mic'd it, and found that the holes in

the side plate were 0.010" too small, there was no way it was going on the master link

pins when it is that tight, so I found a drill bit that was just right, and drilled it out, and

ended up with a 0.004" loose fit, which should be OK....

Some folks have had problems with these master links coming loose,

and recommend using a master link with a tight fitting side plate,

I still might change this one out if I can find one that's better than this one...

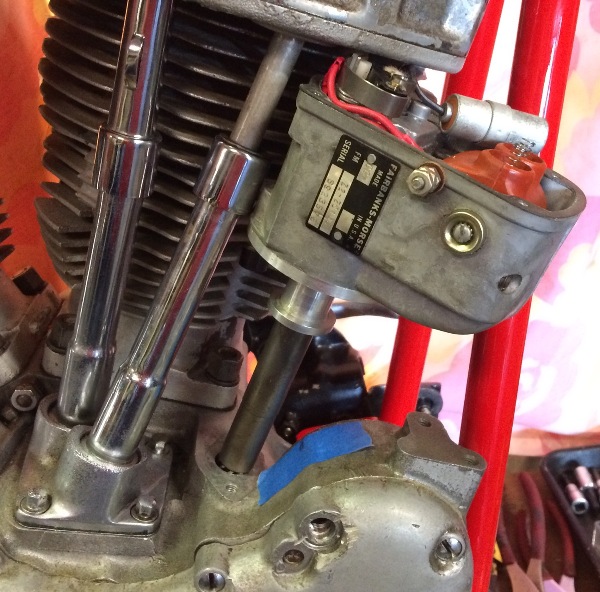

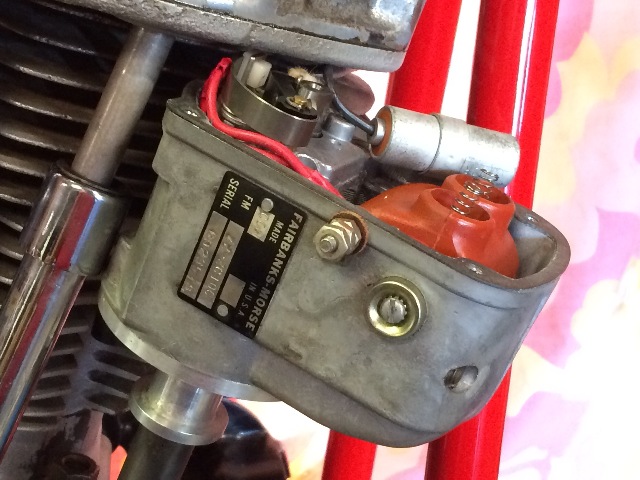

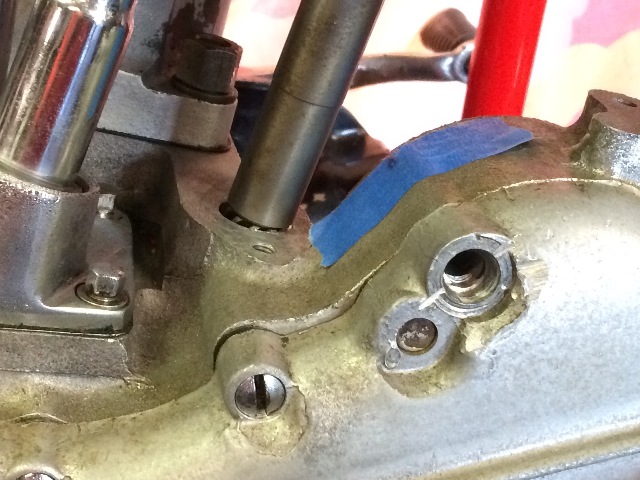

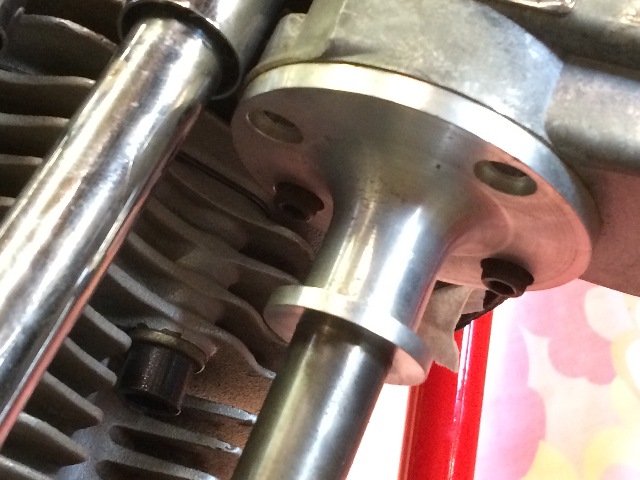

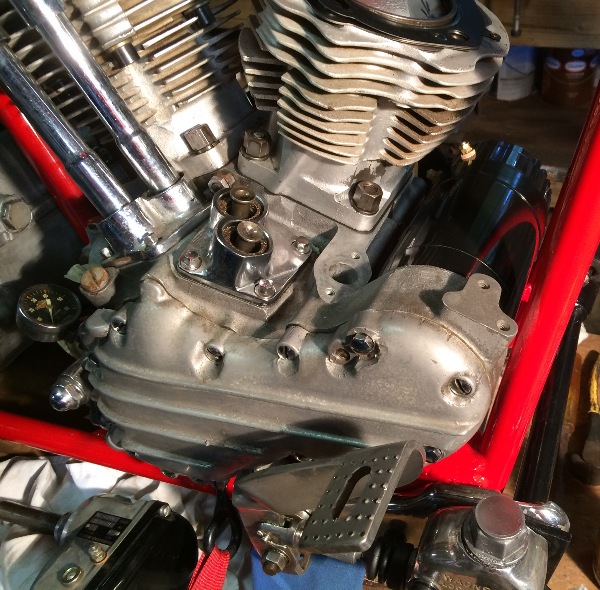

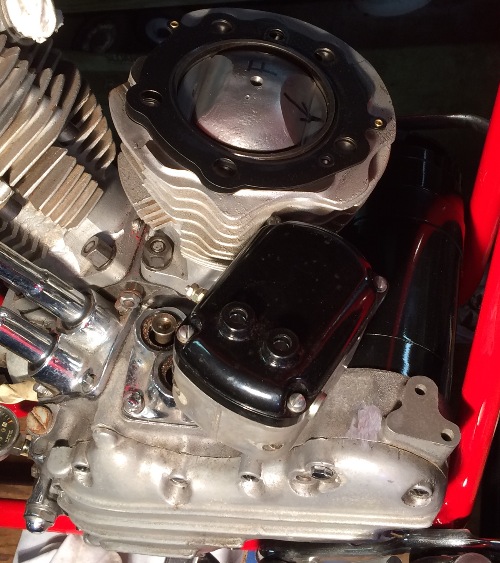

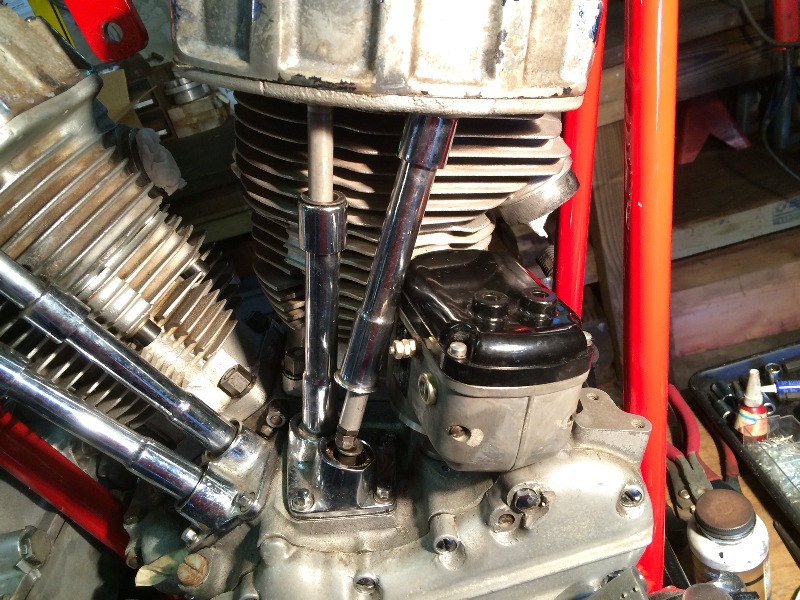

Decided to try putting the new magneto in, without reading the directions first...

With the cap off and pulling the capacitor loose, it almost went in....

Wiggled it around a bit, it was up against the fins as far as it would go...

But the shaft housing just wouldn't line up enough to clear the hole in the case...

Tried taking the allen head screws out of the base, but it was tucked in

under the cylinder head too tightly to get the mag body off of the base....

Finally popped the cylinder head off and it dropped right in the hole,

but is hitting stuff just everywhere else....

That back corner is up against the fins and won't turn more than about 5 degrees....

One of the allen head screws on the magneto base hits the motor case...

But that can be trimmed, and the sharp edge of the base can be beveled for more clearance....

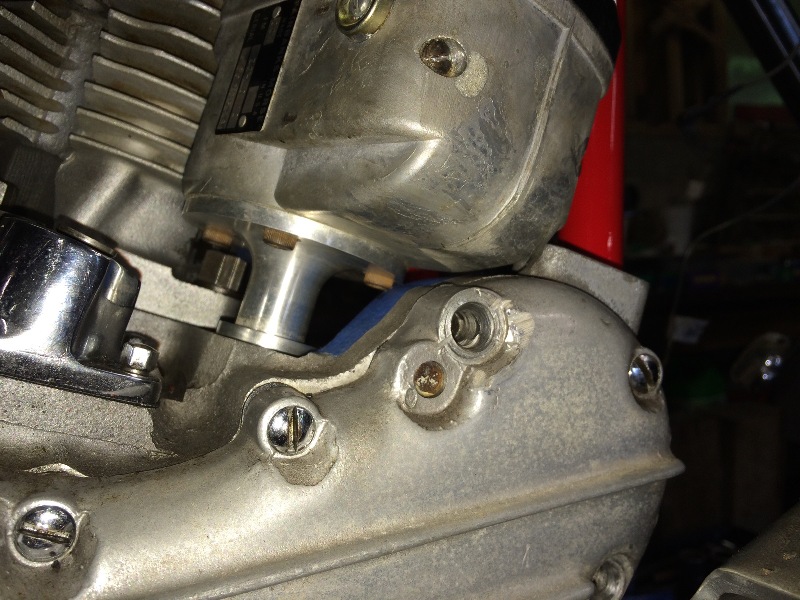

Temporarily removed the offending screw...

And picked up a few more degrees of movement....

I don't want to have to cut that pad in front of the magneto, but might have to...

In the meantime put a flat head screw in where the allen head screw had been....

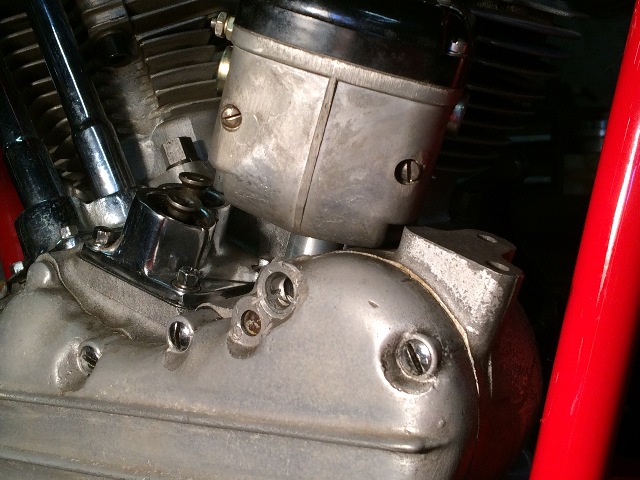

And put the new 12v generator on to make sure it all cleared....

Ground off a bit on the corner of the cap and mag body until it cleared the fins...

Lots of movement now in that direction....

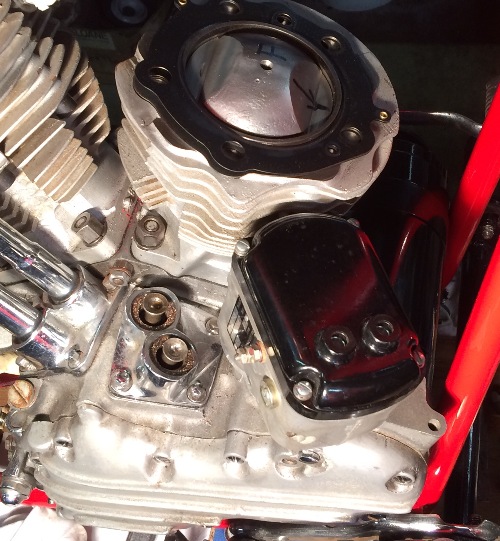

But there will be an issue with the front pushrod, I am sure....

Some clearancing on the bottom of the magneto body....

And a little on the panhead case....

Plenty of movement now, at least until I put the head and pushrods back in...

And in this direction also...

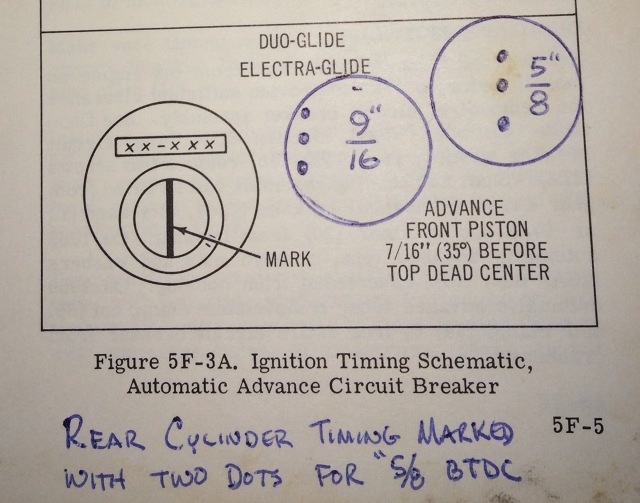

I found this in my panhead shop manual from back in '74

when I first put a magneto on this motor. The firing position marked

on the flywheel for the front cylinder is for 35 deg BTC (7/16"), but for

some reason I had put three centerpunch marks as shown for more advance,

and positioned as shown would give me 9/16" or 5/8" BTC, about 38 deg

and 40 deg BTC. I seem to remember that this motor liked that much advance

and if the correct procedure was used for starting, never kicked back at me...

We shall see....

With the three dots lined up on the flywheel,

played with the gear set on the magneto until I got that narrow lobe just opening

the points, in the middle of the possible movement of the magneto on the motor case...

But when I put the head back on, and the pushrods back, the front pushrod

it too tight against the magneto, more clearancing needed....

It's late, there are two hurricanes threatening Hawaii, and I need a cold beer or three....

More later....